NTO oilseal

- …

NTO oilseal

- …

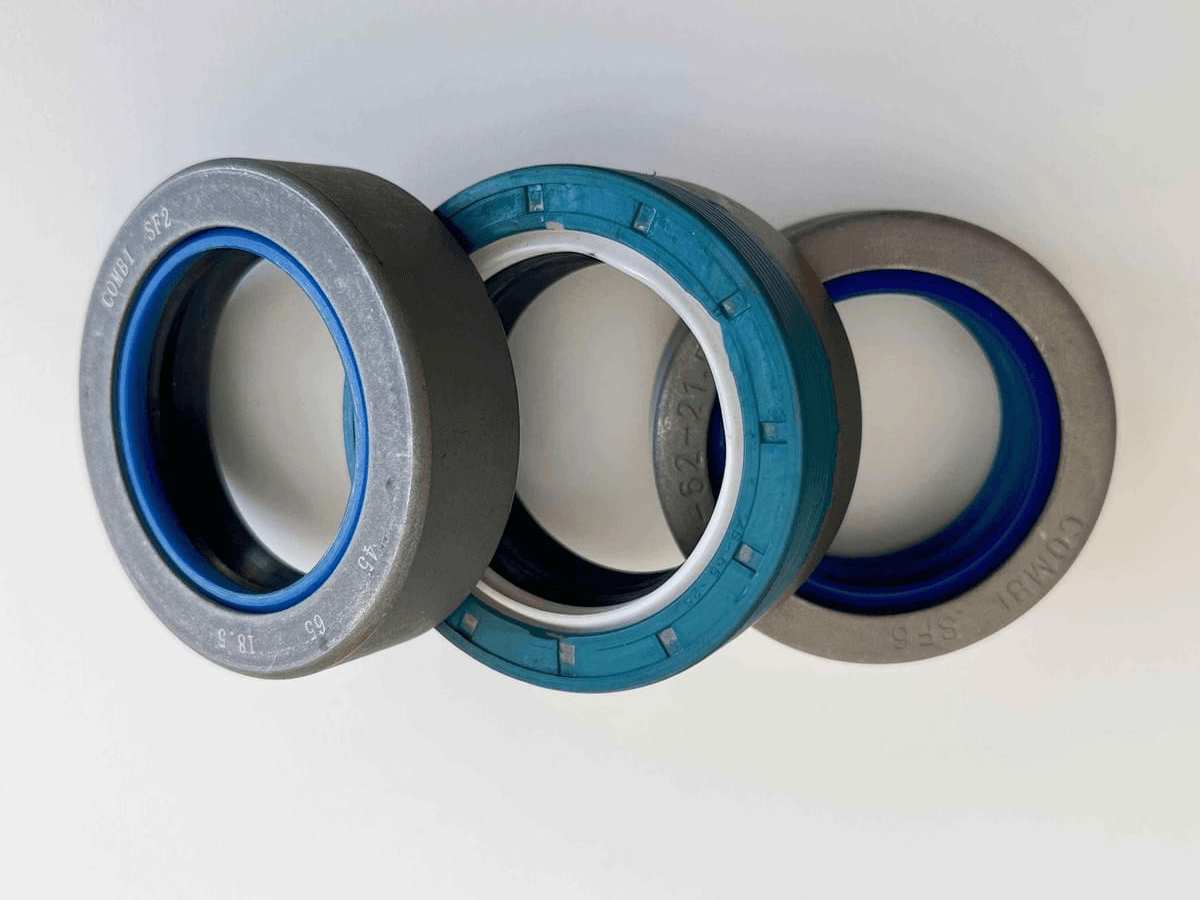

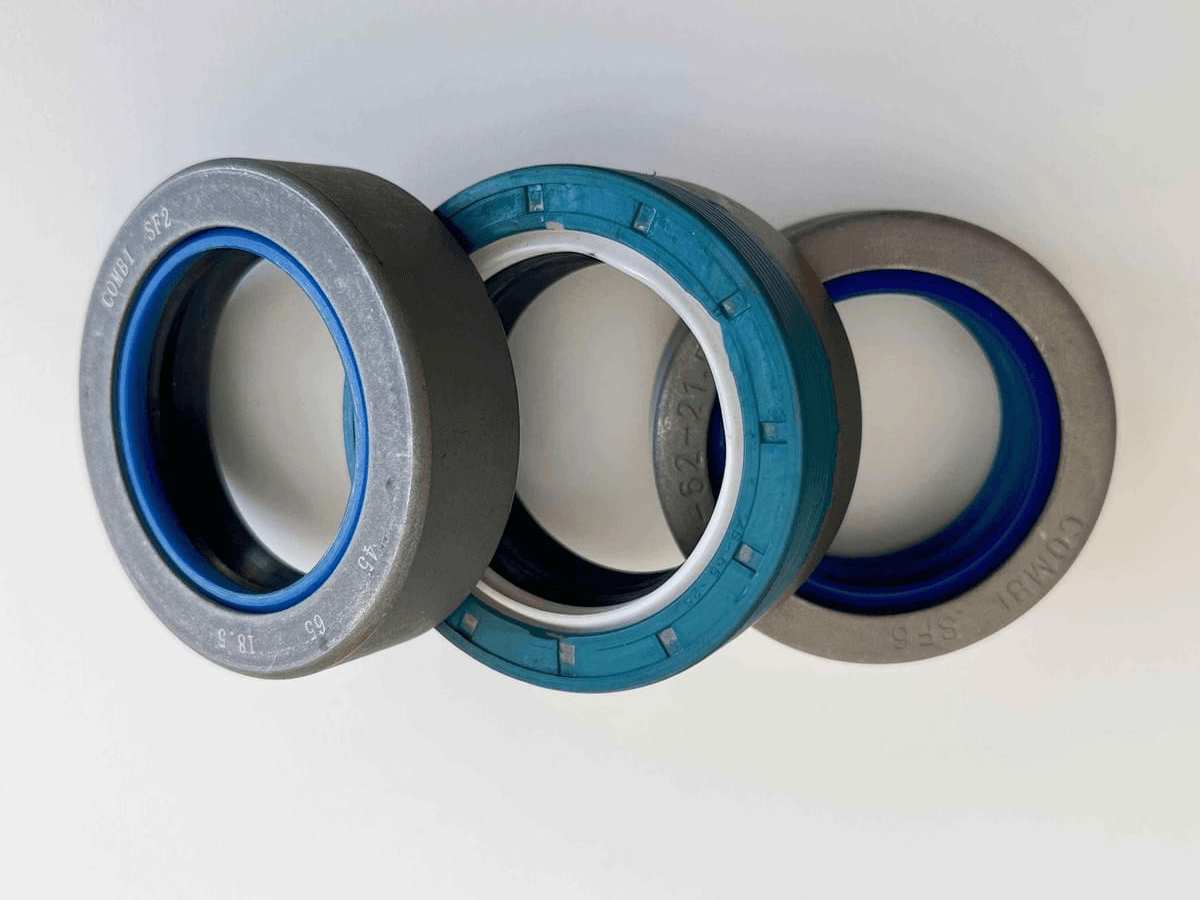

Combined/COMBI OIL SEAL/wheel hub seal

Agricultural machine/tractor/Harvester

Welcome to Nto oilseal

# **Combi Oil Seal: Introduction and Applications**

## **Introduction to Combi Oil Seals**

A **Combi oil seal** (combination seal) is an advanced sealing solution that integrates multiple sealing functions into a single compact unit. These seals are designed to provide superior protection against lubricant leakage and contaminant ingress in demanding applications where conventional single-lipped seals may be insufficient.

### **Key Features of Combi Oil Seals**

- **Dual-Sealing Technology**: Combines primary and secondary sealing lips for enhanced protection

- **Integrated Design**: Merges multiple sealing components into one assembly

- **Space-Efficient**: Eliminates the need for separate seals in constrained installations

- **Versatile Materials**: Available in various elastomers for different operating conditions

- **Spring-Loaded**: Often includes garter springs for consistent sealing pressure

### **Construction and Components**

A typical combi oil seal consists of:

1. **Primary Sealing Lip**: Main dynamic seal that contacts the rotating shaft

2. **Secondary Seal**: Additional barrier against contaminants

3. **Dust Lip**: External protective barrier

4. **Metal Case**: Provides structural rigidity

5. **Spring Mechanism**: Maintains consistent contact pressure

Common material combinations:

- **Nitrile (NBR)** for general purpose applications

- **Fluorocarbon (FKM)** for high-temperature/chemical resistance

- **Polyacrylate (ACM)** for transmission fluids

- **Silicone (VMQ)** for extreme temperature ranges

## **Applications of Combi Oil Seals**

### **1. Automotive Industry**

- **Transmission Systems**: Seals for input/output shafts

- **Differentials**: Pinion and axle seals

- **Engine Components**: Crankshaft and camshaft applications

- **Wheel Hubs**: Combined bearing and seal units

### **2. Industrial Machinery**

- **Gearboxes**: Input/output shaft sealing

- **Electric Motors**: Bearing protection

- **Pumps**: Rotary shaft sealing

- **Compressors**: Crankcase seals

### **3. Heavy Equipment**

- **Construction Machinery**: Final drive and swing circle seals

- **Agricultural Equipment**: Tractor transmission and PTO shafts

- **Mining Equipment**: Robust sealing for harsh environments

### **4. Specialized Applications**

- **Marine Equipment**: Shaft seals with superior water resistance

- **Aerospace**: Lightweight, high-performance sealing solutions

- **Food Processing**: FDA-compliant materials for hygienic applications

## **Advantages of Combi Oil Seals**

✔ **Enhanced Protection**: Dual-sealing action prevents both lubricant loss and contaminant entry

✔ **Longer Service Life**: Reduced wear through optimized lip design

✔ **Simplified Installation**: Single-unit design replaces multiple components

✔ **Space Saving**: Compact form factor for tight installations

✔ **Cost Effective**: Reduces maintenance and replacement frequency

## **Selection Considerations**

When choosing a combi oil seal, consider:

1. **Operating Environment**: Temperature, pressure, and media compatibility

2. **Shaft Speed**: RPM limitations of seal materials

3. **Shaft Finish**: Required surface roughness for optimal sealing

4. **Chemical Resistance**: Compatibility with lubricants and process fluids

5. **Pressure Rating**: Static and dynamic pressure capabilities

## **Installation and Maintenance**

**Proper Installation Tips**:

- Clean shaft and housing thoroughly before installation

- Use appropriate tools to avoid seal damage

- Lubricate seal lips prior to installation

- Ensure correct orientation of primary and secondary lips

**Maintenance Best Practices**:

- Regular inspection for leaks or wear

- Monitor lubricant quality and levels

- Replace at recommended intervals or at first signs of failure

## **Conclusion**

Combi oil seals represent a significant advancement in sealing technology, offering superior performance through their integrated multi-functional design. Their ability to combine multiple sealing requirements into a single component makes them ideal for demanding applications across automotive, industrial, and specialized equipment sectors. By providing enhanced protection against both lubricant loss and contaminant ingress, combi seals contribute to improved equipment reliability, reduced maintenance costs, and extended service life.

For optimal performance, always select combi seals that are specifically engineered for your application's requirements and follow manufacturer recommendations for installation and maintenance.